On June 12, 2024, the team led by Zhong Chao with the Institute for Synthetic Biology of the SIAT, and the team led by Ma Guijun at the School of Physical Science and Technology, ShanghaiTech University, published their research findings in the Science Advances with the title "Conformal and conductive biofilm-bridged artificial Z-scheme system for visible light–driven overall water splitting." This study achieved the construction of a conformally attached conductive biofilm by in situ polymerization of polypyrrole on the Escherichia coli biofilm. By applying a coating of photocatalyst through drop-coating and growing the conductive biofilm in situ on its surface, they were able to construct a semi-artificial photosynthetic system capable of photocatalytically splitting water into hydrogen and oxygen at a stable ratio of 2:1. This system demonstrated long-term operational stability over 100 hours and tolerance to various background pressures, as well as potential for large-scale production. The research represents an application of living energy materials in sustainable clean energy and provides valuable references for the design of systems integrating biology.

Screenshot of the article online

Link:https://www.science.org/doi/10.1126/sciadv.adn6211

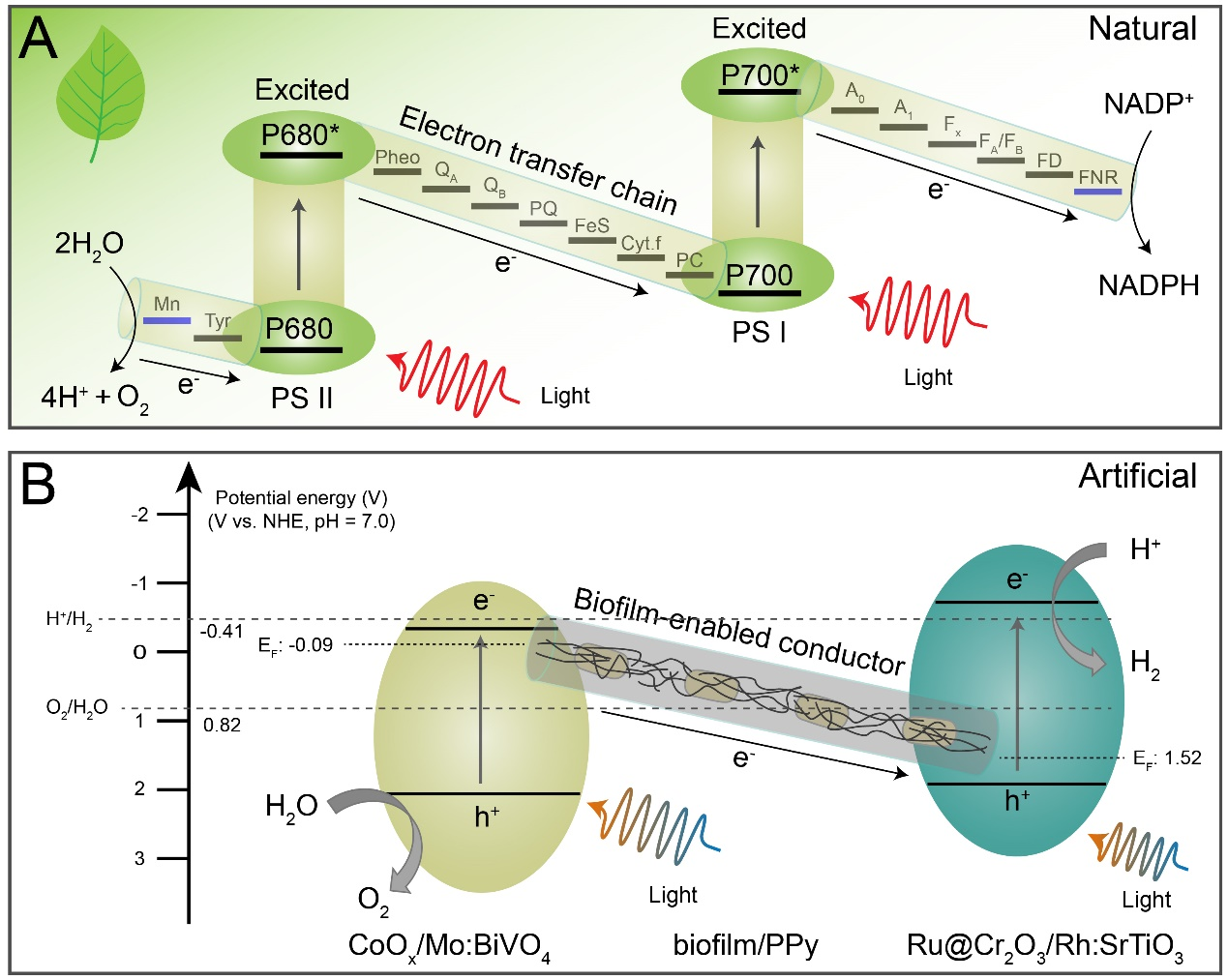

Plants or algae convert light energy into chemical energy through photosynthesis, which adopts the "Z-scheme" for electron transfer (Figure 1A). Photosystem II absorbs solar energy to produce electron/hole pairs, where the hole oxidizes water into oxygen, and Photosystem I transfers the electron through redox protein clusters to the final electron acceptor, ferredoxin. Inspired by nature, researchers proposed the idea of using inorganic semiconductors to mimic natural processes and construct artificial Z-scheme photosynthetic systems to drive the production of high-value chemicals utilizing light energy. Synthetic semiconductor materials have excellent visible light absorption capabilities, allowing them to surpass the efficiency limitations of natural photosynthesis. By integrating biological materials with inorganic semiconductors, it is possible to combine the advantages of both materials to achieve applications such as photocatalytic hydrogen production, carbon fixation, and nitrogen fixation. However, efficient, stable, and sustainable semi-artificial Z-scheme systems are still lacking.

This project proposes a scheme to construct a stable and sustainable semi-artificial hybrid Z-scheme system by combining conductive biofilms with inorganic photocatalysts (Figure 1B). The project selected CoOx/Mo:BiVO4 (abbreviated as [Bi]) with visible light absorption characteristics and high photocatalytic activity as the oxygen-evolving catalyst (OEP) and Ru@Cr2O3/Rh:SrTiO3 (abbreviated as [Sr]) as the hydrogen-evolving catalyst (HEP), and prepared photocatalyst films through the drop-coating method. Subsequently, Escherichia coli biofilms were directly grown on the surface of the photocatalyst coating, and conductive biofilms were prepared through in situ polymerization. The conductive biofilm facilitates effective electron transfer from OEP to HEP under illumination, thereby achieving photocatalytic overall water splitting.

Figure 1: Schematic Diagram of Natural (A) and Artificial (B) Z-scheme Systems

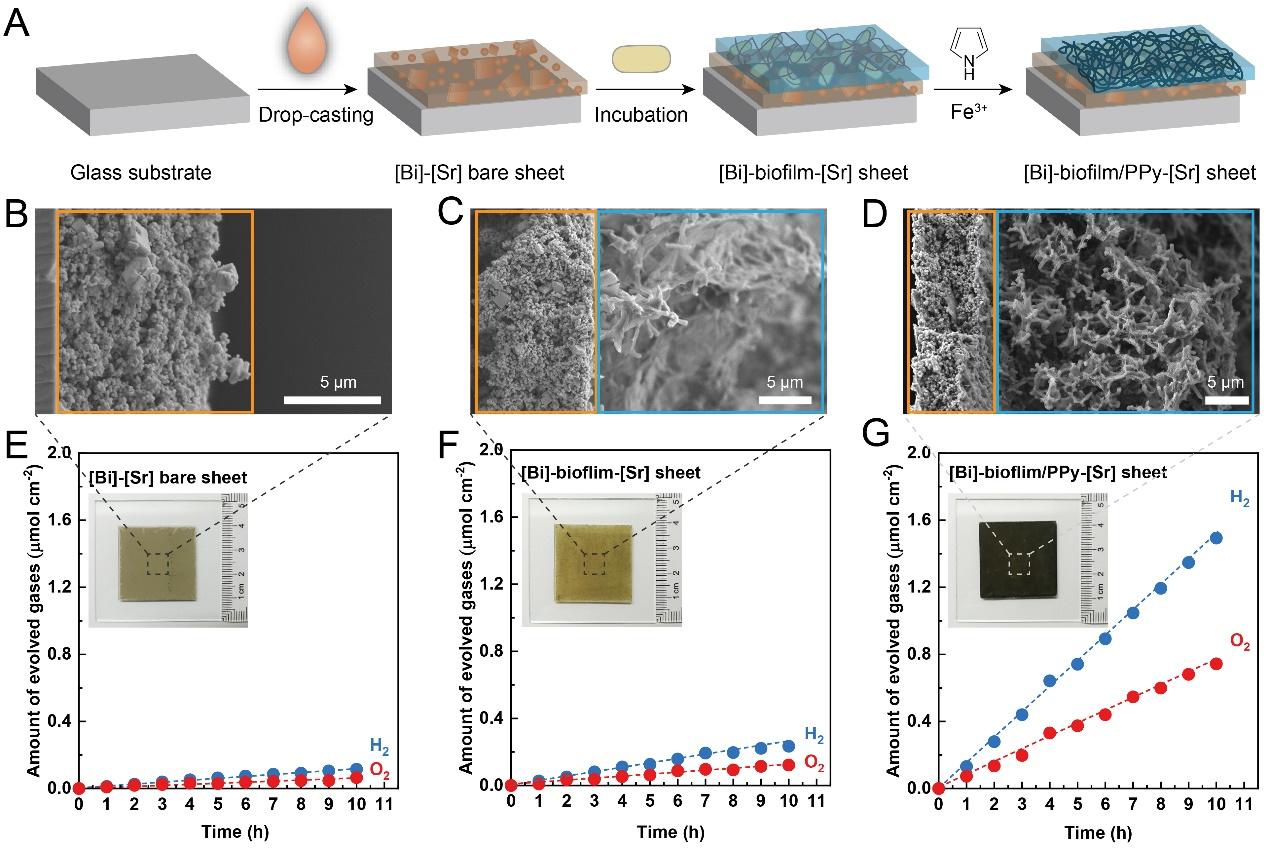

Escherichia coli biofilms are inherently non-conductive in nature. To achieve the preparation of conductive biofilms, this study proposed an in situ polymerization method using polypyrrole (PPy) for the fabrication of conformally attached conductive biofilms (Figure 2). Due to their intrinsic interfacial adhesion properties, biofilms can form conformal coatings on substrate surfaces. The engineered biofilm fibers carry charges, enabling the in situ polymerization of polypyrrole. Interconnected PPy particles impart conductivity to the biofilm. Electrochemical impedance spectroscopy and I-V tests confirmed that the materials prepared by this approach exhibit good conductivity in both liquid and air environments. These tests suggest potential applications beyond photocatalysis in electronic devices and equipment.

To achieve stable and sustainable photocatalytic overall water splitting, this project proposed a layer-by-layer fabrication method for preparing the semi-artificial hybrid coating (Figure 3). First, a photocatalyst mixture coating was prepared using the drop-coating method. Then, a biofilm was grown in situ on its surface, followed by the preparation of a conductive biofilm through in situ polymerization. After transferring it to another substrate using tape, photocatalytic overall water splitting tests were conducted. The ratio of hydrogen to oxygen in the products remained stable at 2:1, indicating successful overall water splitting. Interestingly, the semi-artificial Z-scheme hybrid coating prepared by this method can be peeled off to form a free-standing film, which can withstand sonication without delamination.

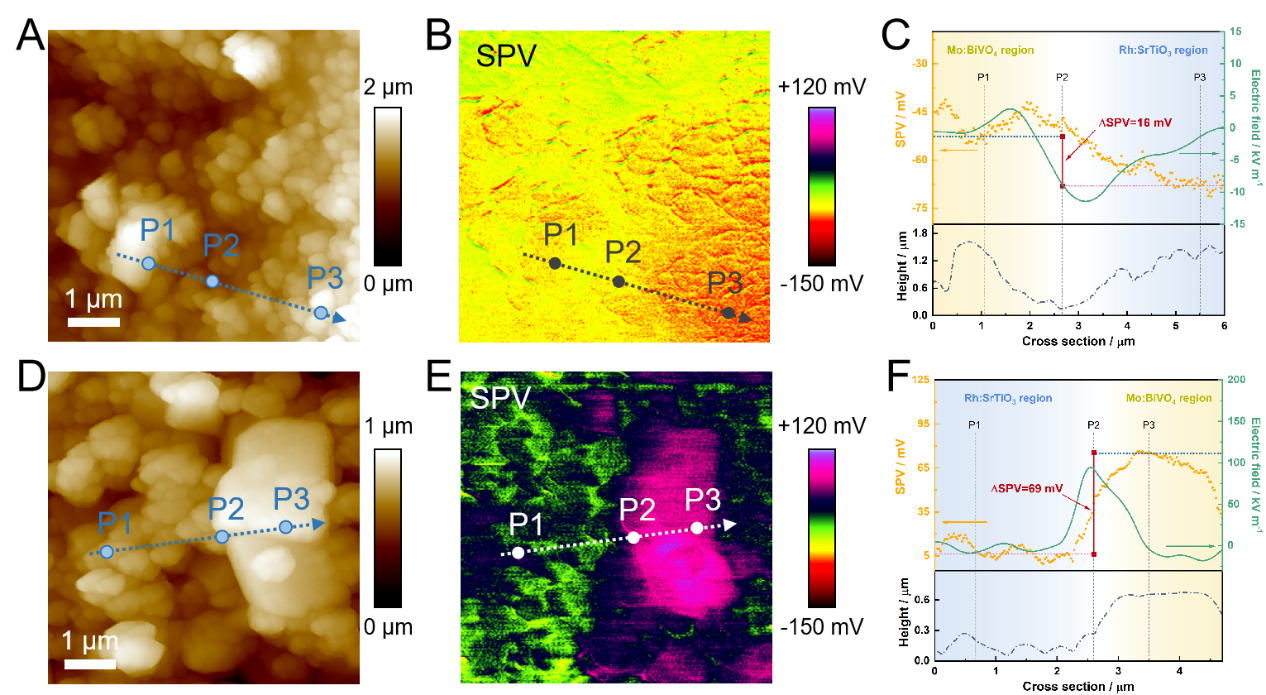

To understand the charge separation effect at the microscopic scale, this project employed photo-assisted Kelvin probe force microscopy (AM-KPFM) to investigate the semi-artificial hybrid coating (Figure 4). Under illumination, the ΔSPV between [Bi] and [Sr] was 69 mV, corresponding to an internal electric field of 95 kV m-1. Compared to non-conductive biofilm coatings, both charge separation and migration were significantly enhanced. Conformally attached conductive biofilms can enhance the charge separation and migration of two semiconductor photocatalysts at the microscopic level, corroborating the experimental results of photocatalytic overall water splitting.

Figure 2 Construction of Conformal Adherent Conductive Biofilm

Figure 3 Construction of the semi-artificial Z-scheme system and its photocatalytic overall water splitting capability test

Figure 4. AM-KPFM Characterization of Semi-artificial Z-scheme System

Figure 5. Semi-artificial Z-scheme System Stability Testing in Photocatalytic Overall Water Splitting Applications

The preparation scheme for the semi-artificial hybrid coating developed in this study is simple and easy to scale up. The project tested photocatalytic overall water splitting on hybrid coatings of different area sizes, and the catalytic efficiency remained essentially unchanged, confirming the potential for large-scale production of the biofilm-based semi-artificial hybrid Z-scheme coatings developed in this study. The hybrid coatings developed in this study have strong tolerance to background pressure, and the catalytic efficiency remains unchanged under atmospheric conditions, overcoming the drawbacks of metal conductive materials that are prone to reverse reactions and significantly reduce catalytic efficiency. The system developed in this study demonstrated long-term operational stability of 100 hours, with stable catalytic efficiency and no structural damage to the material.

In summary, this project relied on engineered Escherichia coli biofilms and developed conformally attached conductive biofilms through in situ polymerization. A semi-artificial hybrid Z-scheme coating was prepared using a layer-by-layer deposition method, exhibiting excellent photocatalytic overall water splitting performance. The system developed in this study is stable, scalable, and sustainable, advancing the development of sustainable living energy materials and providing important references for devices integrated with biology.

The co-corresponding authors of the paper are Researcher Zhong Chao from the Shenzhen Institute of Advanced Technology, Chinese Academy of Sciences, and Researcher Ma Guijun from ShanghaiTech University. The co-first authors are Associate Researcher Wang Xinyu from the Shenzhen Institute of Advanced Technology, Chinese Academy of Sciences, and PhD graduate Zhang Boyang from ShanghaiTech University. This research was supported by funding from the Ministry of Science and Technology's Key Research and Development Program in Synthetic Biology, the National Natural Science Foundation of China, the Shenzhen Key Laboratory for Synthetic Biology Materials, the Shenzhen Municipal Natural Science Foundation Key Project, and the Shenzhen Institute of Synthetic Biology.